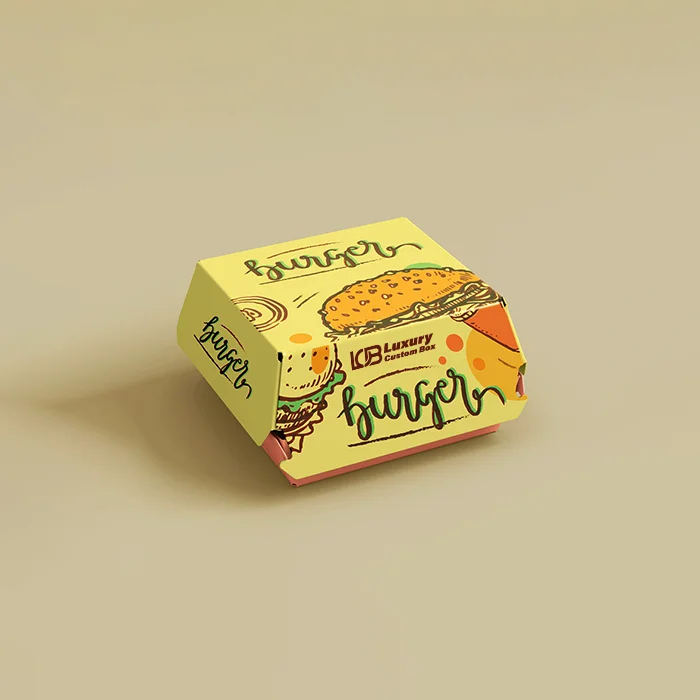

Mini Burger Boxes

Starting From: 0.25$ Per Box

Add to CartGet Custom Quote

Overview

Mini Burger boxes are a type of food packaging product used in restaurants, retail food service, and quick service restaurant takeout to pack prepared burgers in for serving at another location. The boxes help retain heat, control mess and provide a tidy way of handing customers their food. They are employed in businesses as a part of normal food packaging, helping in easy stacking, ensuring safe transport and better handling.

Furthermore, Mini Burger boxes are often decorated with branding, seasonal drawings or menu items to enhance customer recognition. Their fast-food-friendly structure allows you to serve the customer faster, and restaurant businesses seeking to minimize packaging waste without losing ‘reliability and sturdiness’ like that eco-friendly box material is the new popular.

A Reliable Choice in Modern Food Packaging

Mini Burger boxes are for take-away, delivery services, wholesalers and retailers working at an economic pace yet want quality to be maintained. Such containers are used for meal presentation, packaging food and ensuring freshness. Crafted for rapid preparation, hectic service windows and repeat delivery usage, they offer the convenience and stability that one seeks in takeaway boxes.

At a time when seemingly every detail of the customer experience has been microengineered, fast-food packaging matters. A properly sealed box guards against temperature loss and spills, as well as lessening sogginess. Its delivery-safe design makes meals transportable for even the longest of stints. Clients receive hot burgers that don't have to be handed over to them in sopping wrappers or flimsy containers.

Many businesses migrate to environmentally responsible box design as food safety demands and growing environmental awareness have more bearing. Light yet durable design protects food and minimizes waste. Purchase your custom boxes today, and we will continue to make your meals look like a holiday, fresh with benefits. Order now!

What Are The Benefits of Mini Burger boxes?

Heat Retention

Durable insulation field tests under the most demanding conditions that hot fresh taste will last until you're ready to eat, for both dine in and delivery customers. This maintains texture and taste to offer your customers the better quality meals they deserve. Heat locking also means no extra condensation, which would destroy the bun and the insides.

Sturdy Structure

Its solid construction stays put to make sure that burgers won’t quake or tumble when travelling. Its strong design resists crushing and can be stacked on without buckling in busy offices. The use of such containment prevents collapsing and unsightly presentation by companies which make use of these products.

Grease Resistance

Grease-resistant lining prevents interior from leaching through, and makes clean up a snap for staff or guest use. This minimizes stains, ensures cleaner bags and a more pleasant shopping experience for the customer. A tight interior sealing helps keep burgers fresh and guards against buns leaking For dependable packaging throughout every meal, rely on restaurants.

Materials & Structure

Kraft Paper

Kraft Paper is an eco-friendly alternative in packaging with a combination of durability and clean food placement. Quite a few brands like using this material because of its natural appearance and recyclable feature.

Corrugated Board

Cardboard rather than a flimsy paper build, corrugated board provides extra strength in its thick cardboard construction and is perfect for heavy or oversized burgers. The box features an internal fluting that helps it retain its shape and resist pressure.

SBS Paperboard

SBS paperboard provides a premium surface for detailed, high-quality printing and vibrant colors. Restaurants use it for branding and the changing seasons.

Food-Grade Ink & Oil-Resistant Coating

Safe food-grade ink gets in touch with meals, and an oil-proof finish on the outside resists streaks of sauce, cheese, or toppings. These are used in food wrap structures which can be recycled and have overall good performance properties.

Printing & Customization Options

Logo Printing

Restaurants can use this feature to build their brand name with every order. Eye-catching branding turns each box into a little advertisement.

Full-Color Printing

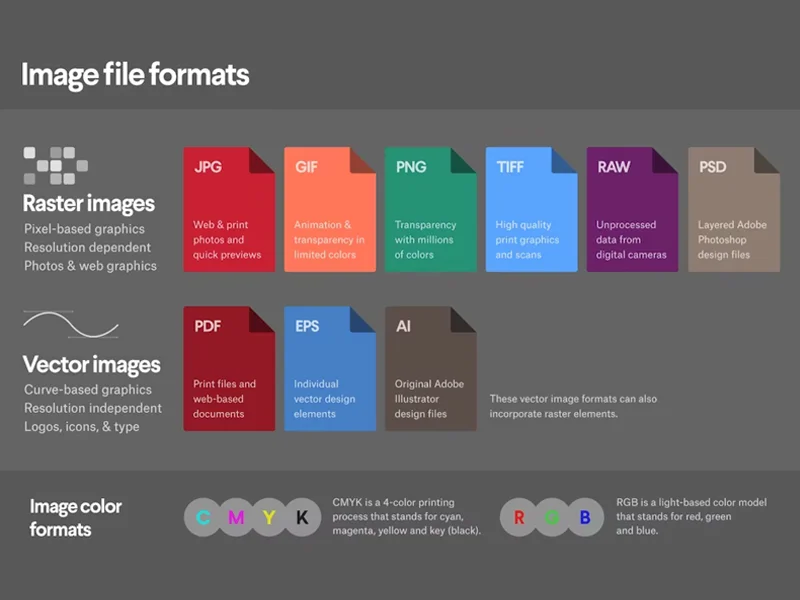

High resolution, full color graphics are ideal for themes and events, holidays Carry Full Color Design to match whatever the occasion. CMYK printing maintains the sharpness of color, whether large or small.

Custom Artwork

Custom designs that help to strengthen brand identity involving seasonal images, quirky illustrations or themed graphics. Flexo printing and digital options cater to both short-run and long-run orders, with matte/gloss finishes available for the perfect look.

Keeping in view your brand, you get to decide the design, color options and presentations of custom Mini Burger boxes or printed Mini Burger boxes that businesses want for their burgers. Add your theme today. Order personalized packaging now for more customers!

Sizes, Styles & Variants

Standard Mini Burger boxes

Ideal for traditional sandwiches, these boxes accommodate single portions with no hassle stacking.

Clamshell Mini Burger boxes

Easy-opening, easy-closing clamshell design is quick and easy to assemble with no sharp edges for safe handling. Fast service is one of the most common applications for them.

Die-Cut Boxes

Die cut forms unique shapes or locks into locking tabs. Great for brand differentiation.

Kraft Mini Burger boxes

Eco Burgers Kraft need to go boxes for eco-conscience restaurants who want sustainability to go.

Window Mini Burger boxes

Windows designs allow customers to see their meal without opening the box.

Available in a variety of sizes, custom sizes and folding options allow restaurants to control presentation and portion management. Whether it’s a giant double Mini Burgeror mini sliders, all dishes earn sturdy wrapping.

Regulations for Food-Grade Boxes for Burgers

FDA Food-Safe Compliance

FDA certified to keep your food safe and free from toxins, since no hazardous or toxic gases are emitted after microwave snacks are heated.

FSC Certification

Supports responsible use of paper.

HACCP Food Safety

These certifications ensure safe production handling, which keeps you protected from unsanitary contamination.

SGS Food-Contact Testing

Testing by SGS verifies each piece complies with food-safety standards.

RoHS Compliance (Safe Ink)

Great for Non-Toxic printing inks since it is RoHS Compliant.

By using certified food packaging, businesses can provide consumers high-quality and safe boxes they can trust.

Which Industries Use Mini Burger boxes?

Restaurants & Fast-Food Brands

These are what high-volume service places use to keep meals hot and pristine.

Cafes

If you are a speciality sandwich or gourmet Mini Burger cafe, clean execution is mandatory.

Food Trucks

Food trucks prepare efficiently packed, compact packaging to enable rapid handoffs.

Takeaway Shops

Mini Burger takeaway owners love the robustness and simplicity of solid burger boxes.

There are a few things that delivery of fast food or street fare requires as much as some speedy, levelheaded service. These are really useful boxes that help keep orders looking and tasting fresh from the point they leave the kitchen.

Why Opt For Luxury Custom Mini Burger boxes?

Premium Printing

Luxury Custom Box printing features crisp, professional print detail that shines at seasonal events and day-to-day service.

High-End Presentation

Presentation adds to the perceived value of your menu and makes people feel interested.

Brand Identity

Between kraft, cardboard, or full color, every box enhances the brand and elevates the customer experience.

From fast food boxes to green Mini Burger boxes, you will find our products in all shapes and sizes that help your brand objectives, customer satisfaction goals, and premium packaging options. Order now and reach for the stars with your brand appeal!

Specification

|

Mini Burger Boxes |

All Custom Sizes & Shapes |

|

MOQ |

Starting from 100 Boxes |

|

Paper Stock |

10pt to 28pt (60lb to 400lb)

|

|

Printing |

Digital (Standard and HD Print),

|

|

Finishing |

Gloss Lamination, Matte Lamination,

|

|

Included Options |

Die Cutting, Gluing, Scored,Perforation |

|

Proof |

Flat View, 3D Mock-up, Physical Sampling

|

|

Turnaround |

5- 8 Business Days, RUSH |

|

Shipping |

Flat |

Frequently Asked Questions

Typical materials include kraft paper, cardboard, corrugated and SBS paperboard, as well as a grease-resistant layer.

Yes. Options are FDA approval, FSC Certification, ISO 22000/HACCP standards, SGS testing and RoHS-compliant inks.

Yes, logo printing is available, full color and event specific artwork is ok.

Absolutely, one option is Kraft, and some are corrugated, depending on what you need in terms of branding and how long you want them to last.

Sizing goes from mini slider to large clamshell, custom on order.

Reviews

Add Your Review

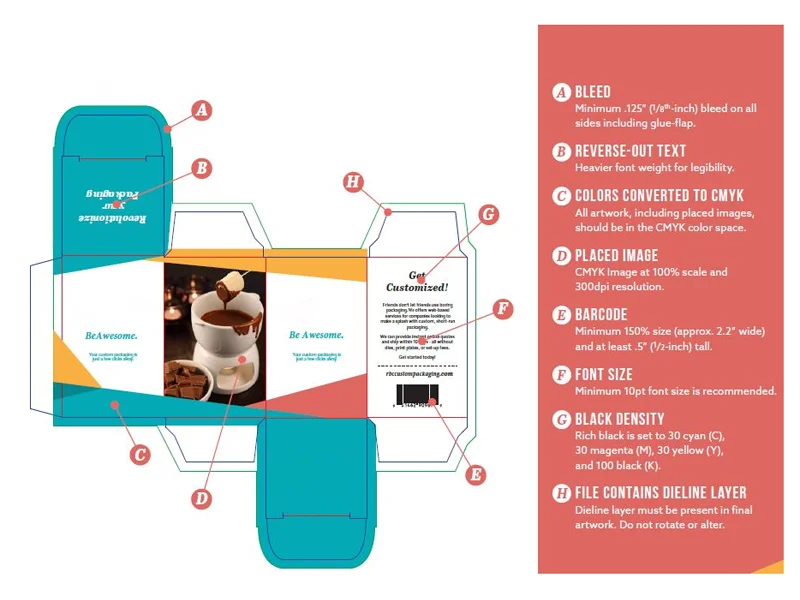

Artwork Setup

Do you need your logo or Artwork? Luxury Custom Box offers a clear artwork setup with bleed, trim and safety for you to follow so that our boxes are printed as intended. Sharp printing, accurate color, and consistent quality are required for all custom packaging.

File Requirements

High-resolution files are preferred for next to no charge in either CMYK or PMS colors. For the best detail, clarity, and reproduction of your uploaded image, we recommend vector files or a print-ready PDF.

Design Accuracy

Proper orientation, page arrangement, and text positioning enable you to print high-quality prints. Luxury Custom Box will not print your artwork without first providing you with a proof after reviewing your art to guarantee that logos, text, and graphic layout appear as planned on your folding paper box.

Pre-Print Review

Each art file receives an in-depth pre-print review. Luxury Custom Box color, size and box structural fit checks are contributing a fillip for avoiding delays, to avoid overspending and quality assurances while packaging with the best quality.

Size Flexibility

Luxury Custom Box gives you full customization options for size to fit your product perfectly. Custom sizes help secure fit and provide a premium top-shelf appearance in retail, gifting and over the counter sales.

Product Fit

Proper sizing creates a snug, secure and professional way to hold both protective pocket and greeting cards. Luxury Custom Box creates brilliant packaging to customize, store and ship any product or valuable item.

Brand Consistency

Custom size offering enables consistent branding beyond product offerings. proportions and visual balance. Luxury Custom Box gives brands the opportunity to brands to present their collections with a consistent packaging identity.

Scalable Orders

From small to full-scale production runs, we offer scalable custom size orders. Brands are assured of constant sizing precision in packaging, whether quantities are small or wholesale.

Offset Printing

Offset printing provides crisp details, exact Pantone color matching, and precise printing of your artwork. This process allows for high-volume output with consistent quality, perfect for the premium packaging that demands clear visuals.

Digital Printing

Digital printing delivers fast turnover and detailed customization. Luxury Custom Box uses this process for short runs, mockups and custom packaging that needs to retain a good portion of its color clarity and design.

Flexographic Printing

In terms of printing, flexographic is limited to simple graphics with larger print runs. This is how Luxury Custom Box does the packing of solid colors economically and produces the same result for larger quantities.

Screen Printing

Screen-printed graphics mean your ink withstands abuse and preserves that soft, lived-in feel. This technique is also used by Luxury Custom Box to ensure that logos and graphics stand out on specific packaging materials that can be printed with a strong contrast and long-lasting result.

Quote Request

Order from the Luxury Custom Box and get a quote. Get your order rolling. We need to know what you had in mind. Styles needed, box size, quantity, and printing are shared by clients in order to guarantee a correct quote and transparent production timeline before we start production.

Design Approval

Once the artwork is approved, Luxury Custom Box reviews your designs and communicates proofs. Approval guarantees lumonics and color, as well as structural alignment, reducing the risk of problems before launching production on a full scale.

Production Stage

Once approved, packaging enters production. To maintain the high quality, Luxury Custom Box has checks and controls over material, printing, finishing and then carries out the strict packaging procedure so that every order delivered strengthens your brand as well as product.

Delivery Dispatch

As soon as orders are finished, they are transferred to safe packing and delivery. Luxury Custom Box arranges shipping schedules to ship packaging in time for clients to display the packaging after receiving their shipments, store or use for a product launch.