Custom Textured Boxes

Get Custom Quote

Overview

Custom textured boxes are used to give your custom textured boxes added dimension that goes beyond what flat packing offers. These tactile packaging boxes use physical touch and visual depth to create a brand experience. Just like real wood, these textures add depth and richness that printed surfaces are not able to achieve.

Textured luxury boxes deliver tactile packaging value that enhances shelf impact and unboxing experiences. Printed texture boxes give your products a unique look in stores and follow the standards of premium packaging boxes needed for luxurious buyers.

What are The Features of Custom Textured Boxes?

Wide Texture Selection

LCB will fulfil your desire for linen, leather, sand, canvas or woodgrain textures to invoke dimensions and tactile interest.

Specialty Paper Quality

The higher the textured card/paper stock, the more detail and durability the card will have.

Logo Printing Compatibility

Printed texture packaging is well-matched for sharp logo prints, foil stamping, embossing and debossing.

Durable Structure

Solid structure maintains textured packaging boxes strength while stored and transported.

Custom Shapes and Styles

It comes with a range of different box layouts to enhance brand displays.

Color Consistency

Color accuracy is also balanced and subtle even on textured surfaces.

What Benefits Do Custom Textured Boxes Provide?

Premium Tactile Experience

Textured surfaces create depth that is felt the moment a customer picks up the product.

Higher Perceived Product Value

The luxury textured boxes convey quality before a product is even unboxed.

Improved Shelf and Unboxing Appeal

Texture brings a depth that flat packaging just can’t.

Ideal Premium Editions

Indie releases earn cachet with tactile cardboard-mailer boxes.

Stronger Brand Identity

Textured packaging is a way for brands to convey luxury without over-the-top graphics.

Sturdy Construction

Products provide weight, rigidity and permanent protection.

Minimalist Design Compatibility

The textured graphic looks good in contrast with the sleek layout and low-key branding.

Materials Used

Textured Specialty Paper

Tactile packaging impact-themed source material.

Rigid Board

Gives sturdy support in luxurious textured boxes.

SBS Paperboard

Slick but grippy on textured wrapping.

Cardboard

Surface for light options.

Kraft Textured Paper

Eco-friendly option offering a natural appearance.

What Styles & Types of Textured Boxes Are Available?

Rigid Textured Boxes

Luxury feel structure with high-end surface.

Magnetic Closure Boxes

Secure and elegant sealing.

Two-Piece Lid & Base Boxes

Classic luxury Custom Box drive with a touch of texture.

Drawer-Style Boxes

Interactive, visually-rich slide-out format.

Foldable Textured Boxes

Compact design, but not at the expense of a good feel.

Gift Boxes with Textured Finish

Perfect packaging for luxury gift brands.

Window Textured Boxes

Product visibility with a pitted surface.

Custom Die-Cut Textured Boxes

One of a kind shapes for one stand-out shelf!

With The Retail Packaging Boxes textured packaging boxes, you get high-quality textured boxes with utmost customizations in textures, printing and finishing. Request a Quote Today and Drive Packaging Production Into The Future.

What Industries Use Custom Textured Boxes?

Luxury Cosmetics & Skincare

Embossed packaging adds to premium product messaging.

Jewelry & Watches

Luxurious textured boxes aid high worth presentation.

Perfumes & Fragrances

Surface texture complements scent branding.

Apparel & Fashion Accessories

Textured boxes of packaging that tout labels and collections.

Corporate Gifting

High-quality packaging boxes lend that credibility to the business gift.

Premium Food & Confectionery

Textured finishes support upscale presentation.

High-End Electronics Accessories

Luxury packaging is all about making that killer first impression.

Required Certifications

- FSC® Certified Paper is a responsible, environmentally appropriate choice for paper.

- ISO 9001 maintains a consistent quality management system.

- ISO 14001 supports environmental responsibility.

- RoHS Compliance ensures the safety of your ink and coating usage.

- REACH compliance is used for the protection of human health and the environment.

- SGS Testing Reports confirm the strength of the material and print quality.

Printing & Finishing Options

CMYK & PMS Printing

True color reproduction on textured surfaces.

Matte Lamination

Soft visual tone to support texture detail.

Soft-Touch Coating

It brings soft contrast to texturized areas.

Foil Stamping

Metallic accents in logos and text.

Spot UV

Gloss differential with texture height.

Embossing / Debossing

Raised or recessed branding elements.

Blind Debossing

Subtle influences produced directly on textured paper.

Why Us?

- 24/7 Availability

- Free Shipping

- Professional Team

- Endless Customization

Specification

|

Custom Textured Boxes |

All Custom Sizes & Shapes |

|

MOQ |

Starting from 100 Boxes |

|

Paper Stock |

10pt to 28pt (60lb to 400lb)

|

|

Printing |

Digital (Standard and HD Print),

|

|

Finishing |

Gloss Lamination, Matte Lamination,

|

|

Included Options |

Die Cutting, Gluing, Scored,Perforation |

|

Proof |

Flat View, 3D Mock-up, Physical Sampling

|

|

Turnaround |

5- 8 Business Days, RUSH |

|

Shipping |

Flat |

Frequently Asked Questions

Linen, leather, canvas, sand and woodgrain are some textures that continue to do well. More specialty textures are available upon request.

Yes, premium printed textured boxes sustain emboss, debossing, gold, silver, and full color printing. Positioning is accurate on textured surfaces.

Specialty textured boxes create a high end look for branding tools in multiple markets. Texture adds perceived value and presentation quality.

We continue to offer custom sizes, structures and die-cuts. Packaging changes according to the size of the product.

Foil stamping, blind debossing and soft touch coatings are good. Spot UV Create contrast in certain spots.

Reviews

Add Your Review

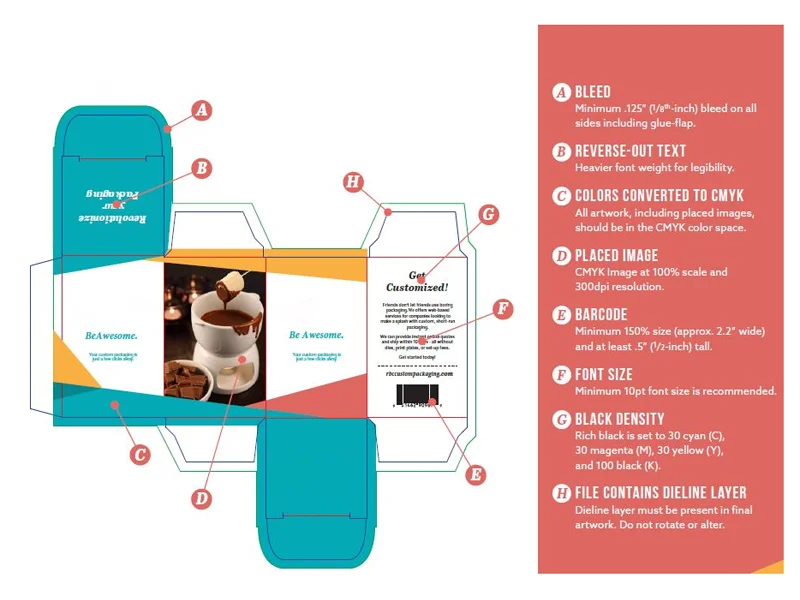

Artwork Setup

Do you need your logo or Artwork? Luxury Custom Box offers a clear artwork setup with bleed, trim and safety for you to follow so that our boxes are printed as intended. Sharp printing, accurate color, and consistent quality are required for all custom packaging.

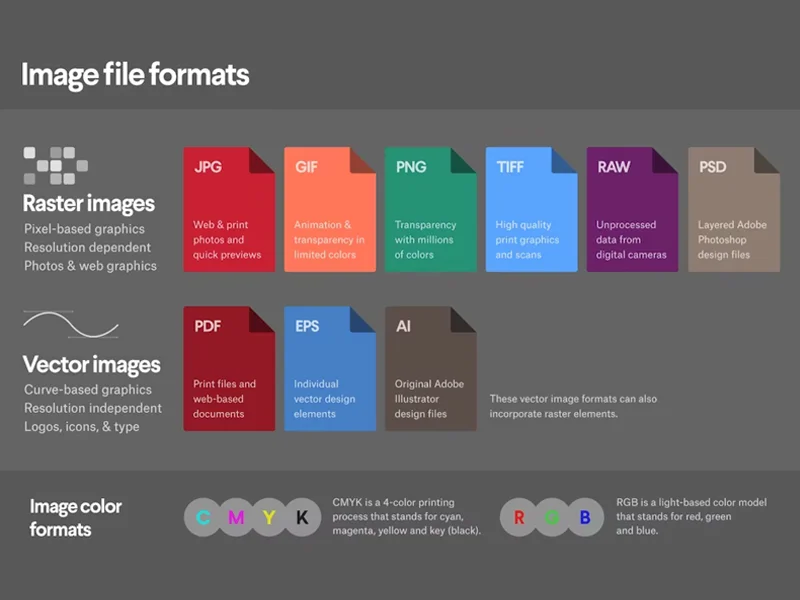

File Requirements

High-resolution files are preferred for next to no charge in either CMYK or PMS colors. For the best detail, clarity, and reproduction of your uploaded image, we recommend vector files or a print-ready PDF.

Design Accuracy

Proper orientation, page arrangement, and text positioning enable you to print high-quality prints. Luxury Custom Box will not print your artwork without first providing you with a proof after reviewing your art to guarantee that logos, text, and graphic layout appear as planned on your folding paper box.

Pre-Print Review

Each art file receives an in-depth pre-print review. Luxury Custom Box color, size and box structural fit checks are contributing a fillip for avoiding delays, to avoid overspending and quality assurances while packaging with the best quality.

Size Flexibility

Luxury Custom Box gives you full customization options for size to fit your product perfectly. Custom sizes help secure fit and provide a premium top-shelf appearance in retail, gifting and over the counter sales.

Product Fit

Proper sizing creates a snug, secure and professional way to hold both protective pocket and greeting cards. Luxury Custom Box creates brilliant packaging to customize, store and ship any product or valuable item.

Brand Consistency

Custom size offering enables consistent branding beyond product offerings. proportions and visual balance. Luxury Custom Box gives brands the opportunity to brands to present their collections with a consistent packaging identity.

Scalable Orders

From small to full-scale production runs, we offer scalable custom size orders. Brands are assured of constant sizing precision in packaging, whether quantities are small or wholesale.

Offset Printing

Offset printing provides crisp details, exact Pantone color matching, and precise printing of your artwork. This process allows for high-volume output with consistent quality, perfect for the premium packaging that demands clear visuals.

Digital Printing

Digital printing delivers fast turnover and detailed customization. Luxury Custom Box uses this process for short runs, mockups and custom packaging that needs to retain a good portion of its color clarity and design.

Flexographic Printing

In terms of printing, flexographic is limited to simple graphics with larger print runs. This is how Luxury Custom Box does the packing of solid colors economically and produces the same result for larger quantities.

Screen Printing

Screen-printed graphics mean your ink withstands abuse and preserves that soft, lived-in feel. This technique is also used by Luxury Custom Box to ensure that logos and graphics stand out on specific packaging materials that can be printed with a strong contrast and long-lasting result.

Quote Request

Order from the Luxury Custom Box and get a quote. Get your order rolling. We need to know what you had in mind. Styles needed, box size, quantity, and printing are shared by clients in order to guarantee a correct quote and transparent production timeline before we start production.

Design Approval

Once the artwork is approved, Luxury Custom Box reviews your designs and communicates proofs. Approval guarantees lumonics and color, as well as structural alignment, reducing the risk of problems before launching production on a full scale.

Production Stage

Once approved, packaging enters production. To maintain the high quality, Luxury Custom Box has checks and controls over material, printing, finishing and then carries out the strict packaging procedure so that every order delivered strengthens your brand as well as product.

Delivery Dispatch

As soon as orders are finished, they are transferred to safe packing and delivery. Luxury Custom Box arranges shipping schedules to ship packaging in time for clients to display the packaging after receiving their shipments, store or use for a product launch.