Finishing color patterns are another important component of luxury custom packaging. They determine what a package looks like, feels like and does when it gets to the customer. In the premium sector of the market, packaging is not just a vessel. It is something that forms part of the product experience and has a lot to do with the quality of the brand.

When a buyer gets their product through a seller, the package is the very first real touch for interacting with the brand. Cleaning up colors, smoothing finishes and honing details can help breed confidence. Low-quality finishing, however, can lower perceived value, even if there’s a great product inside.

This overview will clarify how finishing color patterns function in various phases of luxury gift packaging. It touches on structure, materials, printing and finishing as well as quality control, logistics and collaboration. The aim here is to describe the steps in reasonable detail and show how expert processes combine to create luxury packaging.

Why Finishing Color Patterns Matter in High-Quality Custom Packaging?

Color finishing patterns are greatly effective in terms of the perception of customers. In premier packaging, each visual and tactile element communicates quality and carefulness. High-grade finishing adds to the appearance and takes all the abuse, keeping your phone brand new. It keeps packaging looking luxurious and helps to protect the product from damage during handling and shipping.

Brand Storytelling Through Packaging

Luxury Custom Packaging allows brands to communicate their stories without any words. Brand identity is reinforced by the choice of colors, textures and finishes. Repeated display leads to familiarity, which in turn inspires trust.

When custom printed boxes bear exact colors with neat & clean finishes, they help out in brand presentation. This also allows customers to better remember the brand and relate it with quality.

Tactile and Visual Experience

Premium packaging has to feel as good as it looks. Soft touch coating provides a smooth feel. Matte and gloss variations provide appeal. It amplifies the unboxing experience. Customers frequently make snap judgments on quality, and finishing is a huge part of that.

Protection Meets Presentation

Packaging should protect luxury packaging should protect the product inside. Heavy ends help minimize scratches and damage. All rigid boxes are a high-end packaging option.

It is that balance between beauty and muscle that is required. The finishing color patterns should enhance, not detract from functionality.

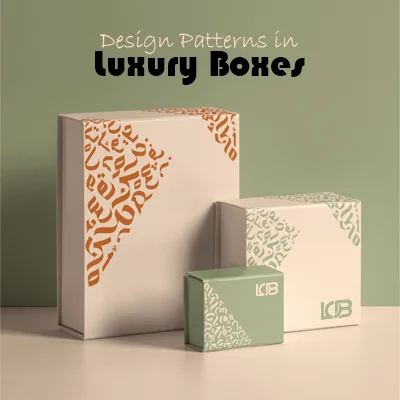

Structural Design Patterns in Luxury Boxes

The excellent packaging must have a reliable and robust construction. It is what makes the box open, close and hold your product in place. It is well constructed, so the finish is crisp and color match up cleanly.

Magnetic Closure Box Designs

Magnetic closure boxes are used in luxury packaging. They make the opening process for smooth and secure. Transport magnets prevent the box from opening during travel.

This construction helps to keep the finishing color patterns matching up around lids and flaps. It also contributes to the “premium” unboxing experience.

Drawer and Two-Piece Rigid Boxes

Drawers are stacked for an added splash reveal. Two piece rigid boxes have that classic, luxurious look. Both are suitable for the highest quality packaging.

These structures require precise measurements. Fit is perfect, and colors match all other panels.

Dielines and Prototyping Accuracy

Packaging engineers create accurate dielines. Dielines instruct cutting, folding and printing. Prototypes are a structure test before mass production.

Packaging prototyping enables early issue discovery. Maintenance of the rigid box structure to hold both the design and finishing done without mistakes.

Material Sourcing & Sustainability Experts

The choice of material also plays an important role in the quality of finish. If you are trying to market a luxury product, then the materials used need to be able to deliver on quality in both printing and finishing that will not only last but maintain appeal over time. Sustainability has also risen in the priority list for brands and customers.

Premium Rigid and Paper Materials

This box is made from rigid greyboard and is heavyweight. Textured box paper enhances the look and feel. It also meant the natural textures of craft paper as a trend in minimalist nature, invites minimalistic designs. These materials are selected depending on the look and feel being sought. Each material interacts differently with inks and coatings.

FSC-Certified and Eco-Friendly Choices

FSC-certified for responsible forestry practices. Sustainable packaging reduces environmental impact. Green materials fulfil modern shoppers’ demands. Recyclable packaging alternatives seek to establish the fine line between luxury and responsibility. Being sustainable doesn’t have to mean compromising quality.

Ensuring Responsibility

Luxury and sustainability are combined. Smart sourcing keeps a premium feel. Rich finishes can still be achieved without materials that impact the environment.

Finishing color patterns features material sourcing experts to get you the colors and performance you want while still meeting your sustainability targets.

Printing Technology Specialists and Color Control

The print tech is where design meets reality. It is critical to print the right print for continuity, finishing color patterns for packaging repeat jobs. Consistency is key when it comes to luxury packaging.

Offset and Digital Printing Methods

For very large numbers, offset printing is the answer. It provides reliable and predictable color. For smaller runs and testing, digital printing is best. Both applications are utilised in luxury packaging depending on the project requirements. Both are capable of high-quality packaging when processed properly.

CMYK and PMS Color Matching

CMYK printing handles detailed images. PMS colors guarantee precise brand hues. Consistent color matching eliminates any variation in the finish between boxes.

PMS-Color is also often indispensable in luxury packaging to ensure that the brand always looks the same. Color management is very important for good results.

High-Resolution Artwork Reproduction

High-resolution files produce sharp prints. Text and logos are crisp and easy to read. Details enhance overall brand presentation.

Printing experts make sure that the artwork is printed in the exact way it was supposed to, so that one will never encounter a blurred or faded message on cardboard custom boxes again.

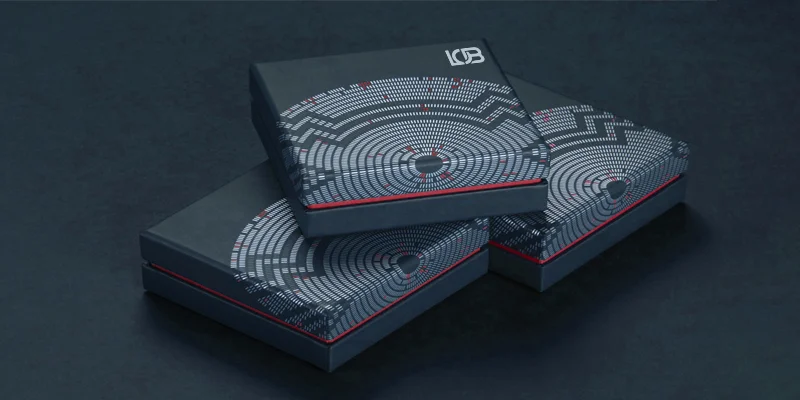

Finishing & Embellishment Experts

The finishing is the stage when packages become characterized as packed. Add-ons transform plain boxes into Custom luxury packaging. These methods create a feeling of depth, texture and visual contrast.

Embossing and Debossing Effects

Embossing raises design elements. Debossing is where the designs are pressed down into the surface. Both create a tactile experience. They are what add depth, without adding more color. They can work well if you are a designer with strong branding and simple designs.

Lamination and Surface Finishes

Soft-touch lamination is smooth to the touch , and it looks high-end. Matte finishes reduce glare. Gloss finishes enhance color vibrancy. The surface may be additionally laminated to provide durability, appearance retention and resilience.

Quality Control & Compliance Patterns

Quality control takes care to be sure every box is up to their standards. In luxury packaging, little errors can have an outsized effect. Consistent checks protect brand reputation.

Foil Stamping and UV Coating

It adds metallic highlights. It highlights logos, or texts. Contrast and shine are added with the Spot UV coating. These luxe finishes make key elements pop. They also enhance aesthetic under various lighting environments.

Print and Color Inspection

Teams inspect color accuracy closely. CMYK vs PMS colors is the comparison given. Misprints are corrected early. This is a feature that makes sure finishing color patterns are the same between production runs.

Structural Strength Testing

Boxes are tested for durability. Edges, corners and closures are rubbing. Product fit is verified. Safe handling and shipping ensure product integrity. It also guarantees a high-quality feeling when customers open the box.

Standards and Brand Guidelines

International packaging standards are followed. Design and finish are dictated by the brand guidelines. Compliance ensures uniform results. Production Standards and Consistencies – Quality control teams help in the production of standards.

Logistics & Fulfilment Specialists

The best packaging is useless if the logistics are a failure in themselves. Finishing color patterns will vary for each client based on the manipulation that takes place during Shipping and Handling. Careful planning reduces damage risk.

Secure Packing for Shipping

Boxes are filled so that no shaking occurs. Protective layers reduce friction. Bulk shipping is carefully arranged. This prevents scratching and other forms of damage at the time of transport.

Damage Prevention in Transit

Strong outer cartons support stacking. Moisture protection is considered. Transit risks are minimized. Logistic packaging teams concentrate on protecting boxes from harm until arrival.

Timely Delivery and Distribution

There is scheduling and supply chain management. Retailers receive stock on time. Customers enjoy reliable fulfilment services. Timely delivery is important for building brand trust and a positive experience.

Benefits of Expert Collaboration in Packaging

Luxury packaging requires teamwork. Each expert votes on the output. Expert teamwork increases efficiency and quality.

Stronger Brand Perception

High-quality packaging increases perceived value. Packaging is what customers associate to the quality of the product. Brand equity grows over time. Finishing color patterns helps tell the story of professionalism and attention to detail.

Better Customer Experience

A flashy unboxing tantalizes the imagination. Clean finishes create positive impressions. Customers feel valued. Good experiences mean repeat sales and referrals.

Competitive Market Advantage

Premium packaging catches the eye on the shelf. It supports premium pricing strategies. Brands gain a competitive edge. When packaging is a brand asset, it contributes to long-term growth.

Proper vs Improper Finishing in Luxury Packaging

| Aspect | Proper Finishing Standards | Improper Finishing Issues |

| Foil Stamping Quality | Smooth application with sharp edges and uniform shine | Patchy foil, dull finish, cracked or missing areas |

| Embossing / Debossing | Even depth, precise positioning, clean impressions | Uneven depth, off-center placement, distorted design |

| UV Coating & Lamination | Flat surface, consistent texture, strong surface protection | Air bubbles, peeling layers, uneven gloss or matte |

| Color Consistency | Accurate CMYK/PMS color matching across all units | Color shifts, fading, inconsistent shades between boxes |

| Structural Strength | Rigid, well-aligned panels with secure closures | Weak joints, bent corners, poor product fit |

| Logo & Artwork Clarity | Crisp text, sharp graphics, correct placement | Blurred prints, misaligned logos, loss of detail |

Conclusion

Finishing color patterns are an important part of the luxury custom packaging. From structural design and material selection, to printing/finishing quality control and logistics. Every single step adds up to the final product. When experts collaborate packaging becomes something more than a box. This becomes a vehicle of brand story telling, customer engagement and long term value.

For businesses wanting dependable packaging solutions and reliable selection of wraps, Luxury Custom Box is the choice as the supplier of wax/sand.wich paper for quality presentation that hasn’t included a special en.trust in our products performance here For all food handling solutions, including preparing yummy sandwiches!

FAQs

Why are expert Patterns important in luxury packaging?

They maintain proper materials and design. These patterns allow the printing and finishing quality to be precisely adjusted. They reduce production errors and increase brand value.

What materials are used in luxury custom packaging?

Rigid greyboard provides strength. Style is added with textured and kraft papers. FSC-certified stock supports sustainability. Eco-friendly coatings are common.

What finishing techniques make packaging luxurious?

Foil stamping adds shine. Embossing and debossing add texture. Spot UV highlights details. Matte and gloss finishes round out the design.

How does proper finishing impact the unboxing experience?

It improves visual appeal and tactile feel. It creates memorable moments and builds customer loyalty.

Can improper finishing damage a brand image?

Yes, visible flaws reduce trust. Poor structure feels low quality. Customers may not repurchase. Brand reputation can suffer.